- Home

- About us

- Product

- DEEFESE & ARMOR

- Materials

- News & Faq

- Contact

In a major step towards enhancing the personal protection of its soldiers, the Indian Army has begun the process to acquire 100,000 ‘AK-47 protected’ helmets. It will be one of the world’s largest procurements of these specialised ballistic helmets. On June 23, the army’s Infantry Directorate kicked off the process by issuing a Request for Information (RFI) on Indian and global helmet manufacturers. The directorate also conducted a preliminary meeting with a handful of helmet manufacturers in New Delhi on July 13. The Request for Proposals will be issued in February next year. The budget for the procurement is not known but assuming each helmet costs Rs 50,000, the army could be looking at a Rs 500 crore order. The new helmets will replace the ‘bulletproof patka’ that has been in service since the 1990s and the stopgap helmet supplied by the Kanpur-based MKU in 2018.

2021-06-23

The General Directorate of the Civil Guard specified to the newspaper El Confidencial Digital the three-year plan to expand the provision of body armor. The plan consists of launching a multi-year purchase during 2021, 2022 and 2023. The result will be an acquisition to acquire a total of approximately 25000 body armor. Thus, in 2021 the Civil Guard will buy 8,400 vests, to then acquire again the same amount in 2022 and 2023. The 25,000 new vests would be added to the 33,000 external citizen security vests that, according to the General Directorate, were purchased in the period between 2017 and 2020. Incorporation of female body armor The request from several associations to get female ballistic vests is finally been taken into account. Women in the military and police departments spoke up about the discomfort of working wearing a men-designed ballistic vest. Finally, the general director of the Civil Guard assured that the female civil guards will receive appropriate bulletproof vests, adapted to their anatomy.

2021-02-16

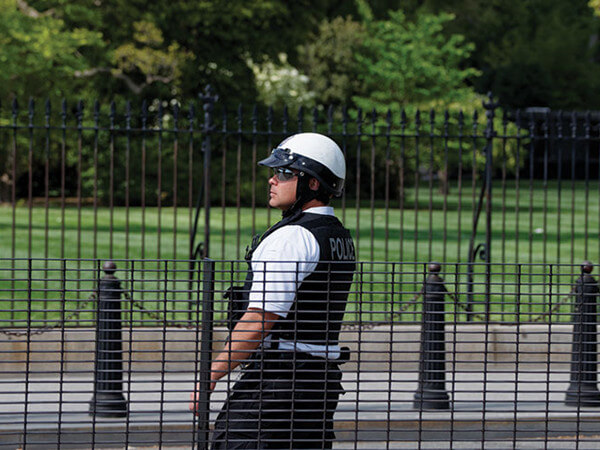

If You Work as a Security Guard Security guards are constantly in danger, especially in the United States where people have the right to arm themselves. It’s impossible to know who could be carrying a concealed weapon. The laws for getting a concealed carry permit are different in each state, which is why it can be very confusing. Depending on where you work as a security guard, this may be of concern to you. For certain types of security jobs, the company would be responsible for issuing the necessary body protection. But many employers prefer to downplay the risks that their security guards face. Or, they may not want to spend the money. So, buying your own body armor to wear on the job would at least protect you in case of danger. If You Live in an Isolated Area If you live outside of town in an isolated area, it’s unlikely that law enforcement would arrive in time to help should problems or some sort of unrest occur. It might be wise to take precautions because there may be a time when you need to defend yourself.

2020-10-20

Law enforcement officers and special teams demand the utmost in performance and versatility from their gear to protect them in high-risk situations. PRE Labs today announced the Amaruq™ Tactical Armour System, a new addition to its lineup of premium tactical carriers. The Amaruq™ – meaning Grey Wolf in the Inuktitut language – is a complete tactical armour system that offers numerous innovations to better protect and equip law enforcement while on duty. “We worked closely with special teams to address their current equipment challenges,” says Brad Field, CEO at PRE Labs. “Through this feedback and supported by our advanced materials research, the Amaruq builds upon our foundation of survivability products to offer the next generation of tactical body armour.”

2019-06-20

Hunan Ketao China Industry Co.,Ltd is the world leader manufacturer in ballistic protection ceramics filed, provide advanced Armor & Defence ceramic solutions to our partners.