- Home

- About us

- Product

- DEEFESE & ARMOR

- Materials

- News & Faq

- Contact

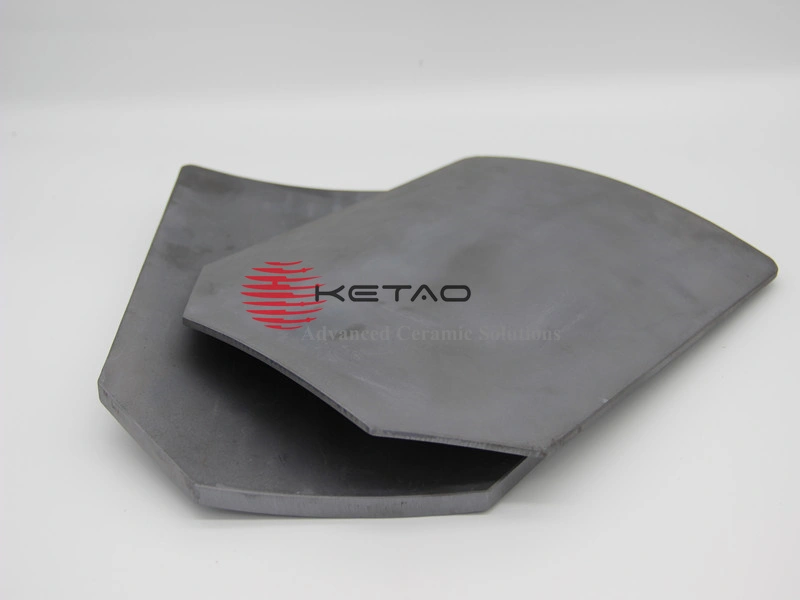

RBSiC ceramics is the main material and technology in armor& defense ceramics. The cost of RBSiC is much lower than SSiC & B4C, and the weight is lighter than Alumina, perfectly balanced the cost and light weight.

Firstly ,silicon carbide and binder (such as resin) are made into composite semifinished product by pressing molding. Secondly the composite semifinished product is heated in an inert atmosphere, the binder is pyrolyzed into glassy carbon, and the semifinished produc change to a composite material formed by porous carbon and silicon carbide. Finaly the machined semifinished produc is heated in molten silicon under an inert atmosphere to complete the reaction sintering process.

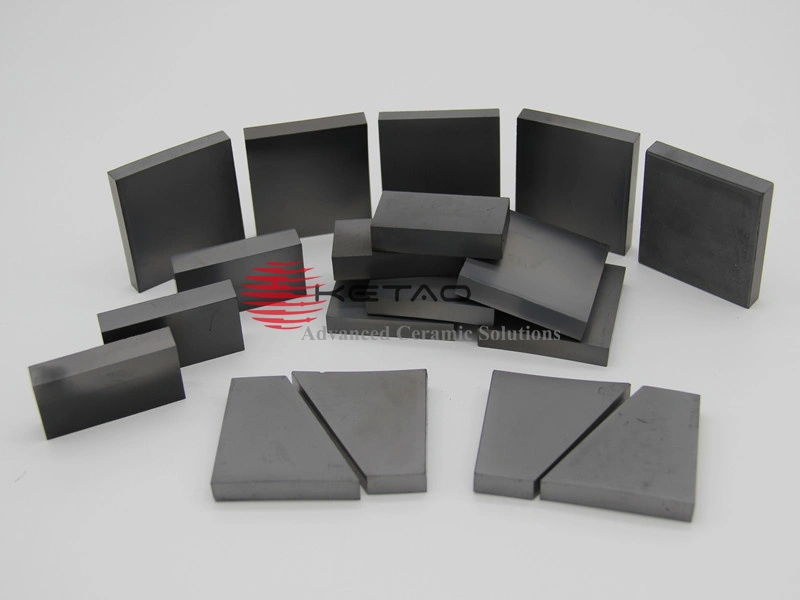

SSiC ceramics are made of high-purity, ultra-fine silicon carbide powder as raw materials, adding a small amount of sintering aids, such as boron, carbon, etc., in an inert gas or vacuum atmosphere at atmospheric pressure, and sintered at a high temperature of 1950-2100°C. The SSiC product is almost completely dense. SSiC ceramic's surface is smoother, the density is higher, and the hardness is higher than that of RBSiC.

B4C ceramics have the advantages of low density, high hardness, high modulus, high thermal conductivity, high melting point, excellent wear resistance, etc., and B4C have high flexural strength and fracture toughness. It is a good armor protection material. Boron Carbide ceramics also have the characteristics of low density and light weight. In the same volume, it is lighter than alumina ceramics, but the hardness is several times higher. Therefore, it is widely used for Armor protection.

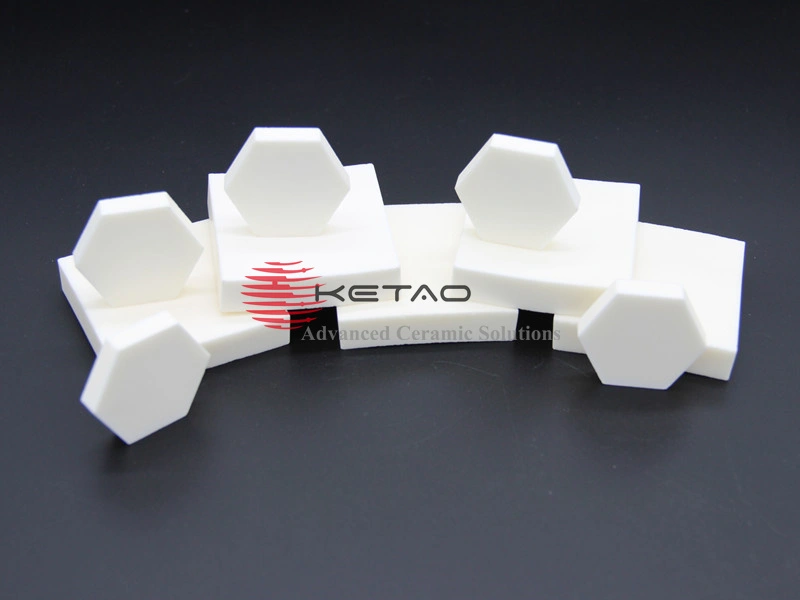

As an ionic bond compound, Alumina ceramics have strong chemical bond strength, high melting point (2050°C), good oxidation resistance and chemical inertness. The sintered alumina products have smooth surface, stable dimensions and low prices, so alumina ceramics are widely used in various armor & defense area.

Hunan Ketao China Industry Co.,Ltd is the world leader manufacturer in ballistic protection ceramics filed, provide advanced Armor & Defence ceramic solutions to our partners.